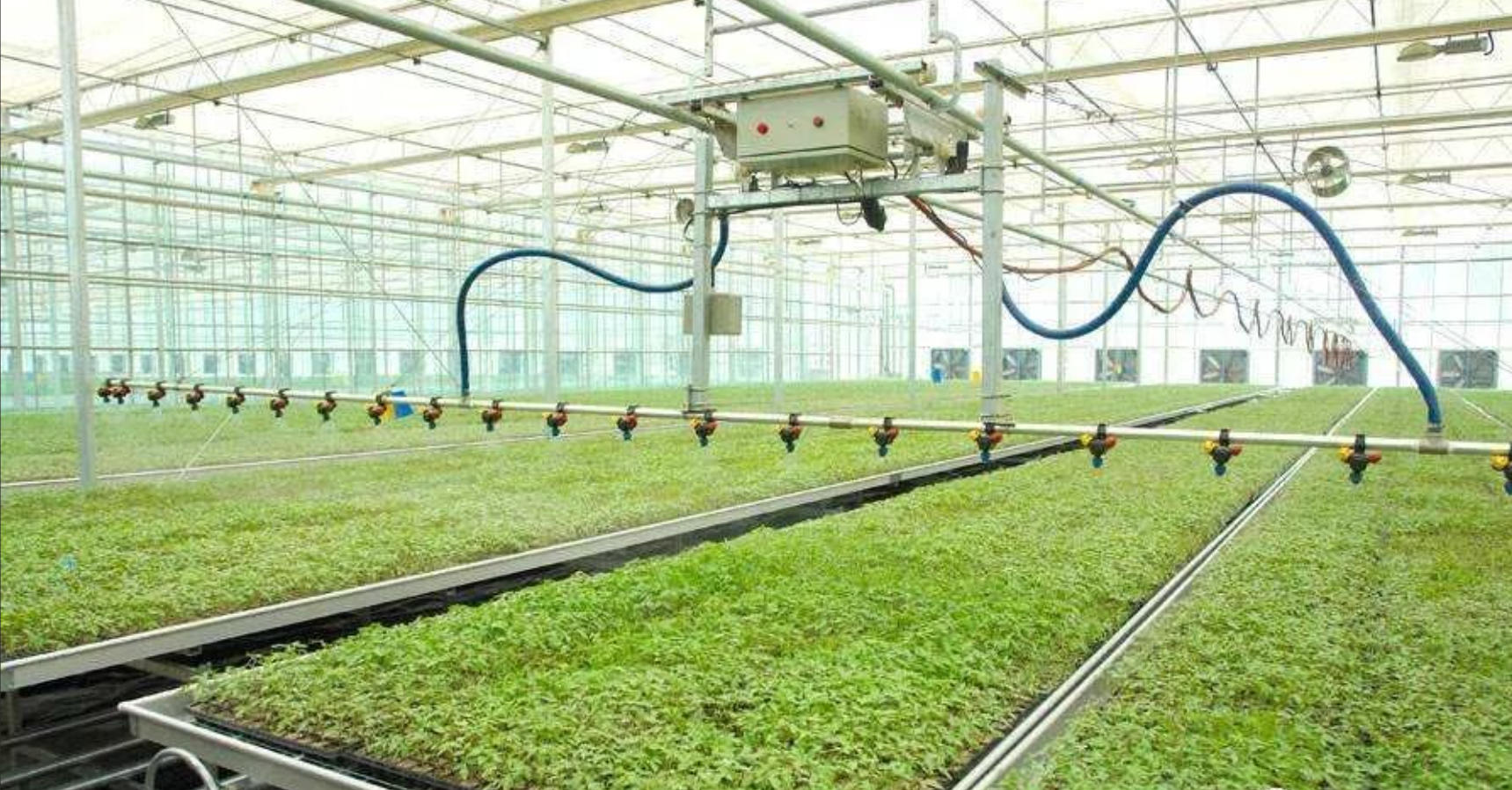

Major leading promotion technology for modern facility agriculture: Intelligent three-dimensional seedling transportation and management system

I. Basic situation

Seedlings are the key to vegetable production. Plug seedlings are the most common production mode of vegetable seedlings in my country. The low efficiency of seedling production and transportation has seriously restricted the quality and efficiency improvement of the vegetable industry. Beijing Huanong Agricultural Engineering Technology Co., Ltd. uses the concept of factory production to develop an "intelligent three-dimensional seedling transportation and management system" to improve labor productivity.

The system is aimed at the production scenario of plug seedlings, with the planting bed as the transportation unit; in the seedling planting area, two ground transportation methods, rail system and automatic navigation robot, are used; in the centralized operation workshop, a combination of ground transportation and aerial overhead crane suspension transportation is used to establish a seedling production and transportation network with full automation, realizing the full automation of seedling transportation and management in the production process.

II. Technical points and results

1. Technical points

(1) Establish standardized operation procedures and operation paths. Develop and formulate standardized operation procedures with commercial seedlings as the target object, which are applicable to more than 90% of fruit and vegetable seedlings and grafted seedlings. At the same time, the spatial layout standards for the fully automated production of seedlings were established, forming a production operation route with precise local operations and smooth overall operation.

(2) Research and development of key equipment. Based on comprehensive consideration of electromechanical equipment, operation node equipment and distance, key equipment such as high-precision and fast overhead cranes, automatic navigation vehicles, germination chambers, healing chambers, germination chamber multi-layer plant automatic conveying equipment, and tray in and out machines were developed to form a complete set of fully automated systems, solving the problems of poor stability and low accuracy of long-distance three-dimensional conveying of plants under high humidity conditions. The conveying efficiency can reach 4,000 trays/hour.

(3) Research and development of production scheduling management system. Using a combination of wireless and wired communications, a full-operation chain production management system of "seedling management, production materials management, and production operation management" was established, including 6 modules such as PLC configuration module, basic information maintenance module, background crop planting management module, and task execution module, realizing real-time online collection, transmission and management of planting data, as well as intelligent remote operation control and traceability.

2. Cost reduction and efficiency improvement

(1) Save labor and production costs. Except for grafting and packaging, other links of seedling production are mechanized and connected in series by an intelligent conveying system to achieve full automation of the operation.

(2) Improve seedling quality and yield rate. The fully automated production system enables water and fertilizer management and various equipment operations to be performed under automatic scheduling, reducing human errors and deviations, and improving seedling consistency and overall quality.

III. Application conditions and requirements

The seedling intelligent three-dimensional conveying and management system is suitable for large multi-span greenhouses and cluster solar greenhouses. The specific application conditions and scenario requirements are as follows:

1. The greenhouse planting area is more than 1 hectare;

2. The cluster solar greenhouse needs to have a centralized operation area, a partially closed conveying channel, and a flat site;

3. The operators can strictly follow the regulations after system training;

4. The investment is more than 2 million yuan.